The Skyscraper Museum is devoted to the study of high-rise building, past, present, and future. The Museum explores tall buildings as objects of design, products of technology, sites of construction, investments in real estate, and places of work and residence. This site will look better in a browser that supports web standards, but it is accessible to any browser or Internet device.

THE CONCRETE FACTORY

Just as steel was the standard material for skyscrapers from the 1880s, reinforced concrete became the building material of the modern multistory factory. In both the U.S. and Europe in the late 19th�century, engineers, architects, and builders began to develop and patent systems of construction using the ancient material of concrete, but reinforced with metal rods known as "rebar" or other shaped metal used to strengthen columns, beams, girders and floors.��Favored for its strength, economy, ease and speed of construction, and fireproof qualities, reinforced concrete was ubiquitous by the turn of the 20th century.

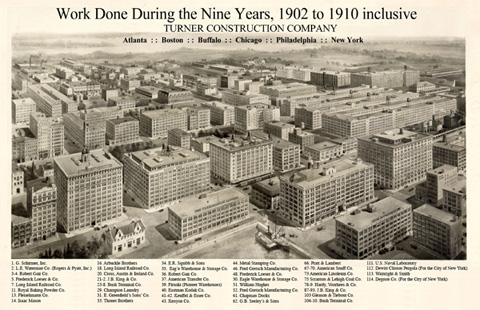

Turner City

Turner City Courtesy of Turner Construction Company

The illustration known as Turner City, the first of a series that continues to this day, is a compilation of structures completed by the company between 1902 and 1910. Henry Turner, a pioneering engineer of reinforced concrete systems and the founder, with partner DeForrest Dixon, of Turner Construction Company, commissioned illustrator Richard W. Rummel to create a visual that would advertise their collective accomplishments.

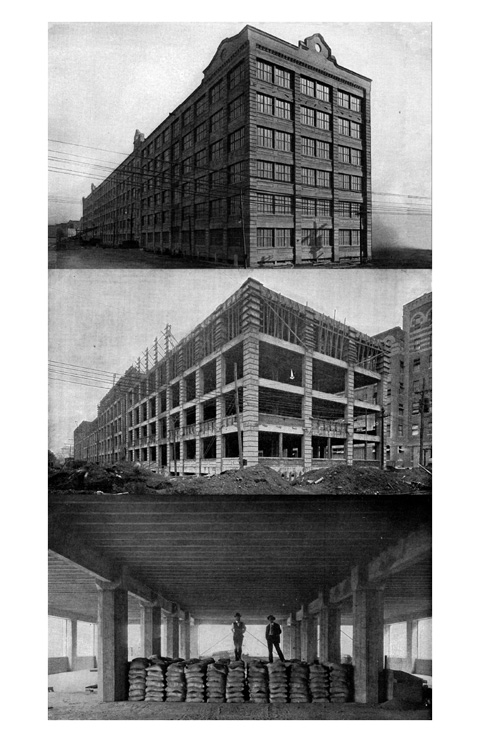

Views of Bush Model Factory No. 2. Reinforced Concrete in Factory Construction, The Atlas Portland Cement Company, 1907. Collection of The Skyscraper Museum

Most of the buildings in Turner City are factories and lofts of a decidedly generic character. The buildings were less the designs of architects than they were the application of a system of construction. A typical example was one of Turner's earliest projects, a 1906 factory loft building for the Bush Terminal Company in Brooklyn, pictured in the frame at right. Known as Bush Model Factory No. 2, the 75 ft. by 566 ft. design served as a template for additional lofts built in the industrial park (No. 23-8 and 106-10 in the illustration). In total, 26 loft factories and 118 warehouses were built through 1925 for Bush Terminal.

Building Systems

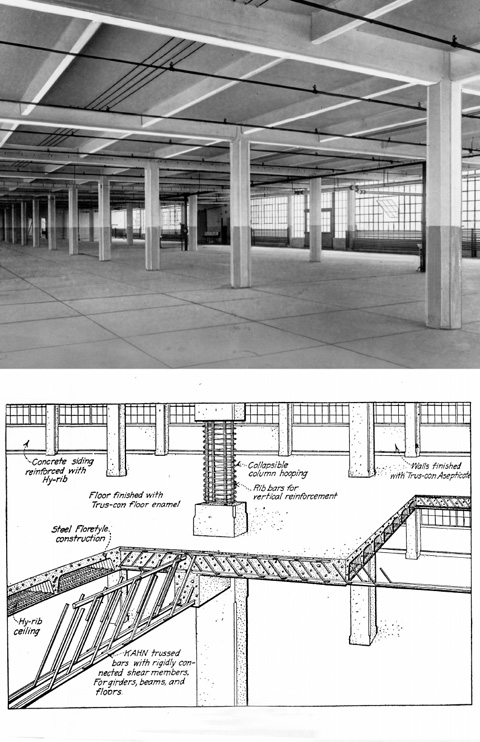

The simple structure of regular columns and slabs of concrete allowed for almost continuous expanses of windows that created well-lit and ventilated spaces. Standardized structural systems and mass-produced parts and supplies kept costs down.�Patented systems used by design and construction fell into two main groups: beam-slab and flat-slab. Examples are the Kahn Trussed system and Turner flat-plate slabs and mushroom columns.

Beam-Slab: Kahn Trussed System

Around 1902, the�Kahn brothers, the prominent factory architect�Albert and engineer Julius, developed one of the most successful early patented systems of reinforced-concrete construction in the early 1900s. Their innovation was a partially prefabricated system of�post-and-beam construction: vertical�columns supported horizontal beams and joists, which in turn supported the floor slab.�Steel reinforcing bars were pre-assembled and shipped to the site where workers simply�unfolded the bars, rather than placing each one individually.�The "trussed" horizontal bars were connected with struts set at a 45-degree angle to efficiently resist shear. Columns were reinforced with a collapsible metal spiral hoops surrounding the vertical bars.

Top: Ford Motor Company Highland Park Plant, Michigan 1909

Courtesy of Albert Kahn Associates

Bottom: Diagram of the Kahn System from Concrete Engineer's Handbook

Hool, Johnson et al., 1918. Collection of The Skyscraper Museum

Flat-Slab: Turner Four-way Flat-plate System

In 1909, C.A.P. Turner developed a system using four-way flat-plate slabs and mushroom columns that made possible�very thin floors.�Around the columns, the slab was reinforced�with capitals in the shape of an inverted cone.�The absence of beams and joists allowed simpler mechanical and electrical installation, and thinner slabs used less concrete and enabled light from large windows to penetrate more deeply into the interior.�In addition, not having to erect formwork for the beams accelerated construction and reduced labor costs. This system of flat-slab and mushroom columns became a specialty of Turner Construction.

Top: U.S. Navy Fleet Supply Base, Storehouse No. 1. Photograph by Rob Tucher

Library of Congress, Prints and Photographs Division, HAER NY, 24-BROK, 56-13

Bottom Left: Diagram of Reinforcing for Mushroom System Concrete Steel.

C.A.P. Turner, 1909. Retrieved from www.archive.org

Bottom Right: Mushroom System Under Construction from Reinforced Concrete in Factory Construction, The Atlas Portland Cement Company, 1907. Collection of The Skyscraper Museum