The Skyscraper Museum is devoted to the study of high-rise building, past, present, and future. The Museum explores tall buildings as objects of design, products of technology, sites of construction, investments in real estate, and places of work and residence. This site will look better in a browser that supports web standards, but it is accessible to any browser or Internet device.

BURJ KHALIFA

Architectural model on loan from SOM

Dubai, United Arab Emirates, completed 2010

828 m/ 2,717 ft/ 163 floors

Developer: Emaar Properties

Architect: Skidmore, Owings & Merrill (SOM)

Structural Engineer: SOM | Hyder Consulting

G.F.A.: 3.3 million sq ft

At 828 meters/ 2,717 feet, Burj Khalifa is the tallest building in the world in all three categories of the Council on Tall Buildings and Urban Habitat. Taller than two Empire State Buildings, it surpasses the current second-tallest structure, Shanghai Tower, by nearly 700 feet.

The altitude of its highest occupied floor is 1,918 feet, which means that the top 800 feet – 30 percent of the tower’s height – was designed, at great expense and through a remarkable feat of engineering and construction, purely as an aesthetic feature and to decisively assert its world-record height. Currently, though, the world’s next title-taker is in the early stages of construction in Jeddah, Saudi Arabia: although its final height has not been disclosed, the Kingdom Tower will reach or exceed 1,000 meters, or a kilometer in height.

Principally residential, the 163-story Burj Khalifa is a mixed-use building that reverses the normal planning logic: the lower stories are occupied by a boutique hotel, above which there are condominium apartments up to the level of the first observation deck on the 124th floor. The top 37 floors, those with the smallest floor plates, are reserved for elite corporate office suites, save for a second observation deck on the 148th floor.

Burj Khalifa is the centerpiece of Downtown Dubai, a 500-acre commercial and residential complex.

BURJ KHALIFA WIND TUNNEL MODEL

Burj Khalifa wind tunnel model.

On loan from RWDI Consulting Engineers

The “Y” shape and extraordinary height of Burj Khalifa was a result of its innovative “buttressed core” structural system. (The tower’s structural engineer William Baker explains the system in a video on the screen across the gallery.) The form tapers as it rises, and the scalloped sections spiral as they step up the tower in ways that were determined by tests in a wind tunnel with models like this force-balance model which measures vibration.

Integrating wind-engineering principles designed to “confuse the wind” (also known as “vortex-shedding") had a significant impact on the shape and details of the tower. These included softening of the shape of the scalloped buttresses and the reversal in the direction of the stepped spiral to the prevailing wind.

Burj Khalifa was designed as an all reinforced-concrete building with high-performance concrete from the foundation level to level 156; above, it is topped with a structural steel braced frame from level 156 to the highest point of the tower. While several structural options were considered (including a composite system), high-performance concrete was selected as the primary structural material for the tower because of its mass, stiffness, high strength, moldability, continuity, and pumping ability. Speed of construction due to its advanced formwork system was key, as well as the advantages that concrete offered for residential buildings, because it insulates against sound between floors.

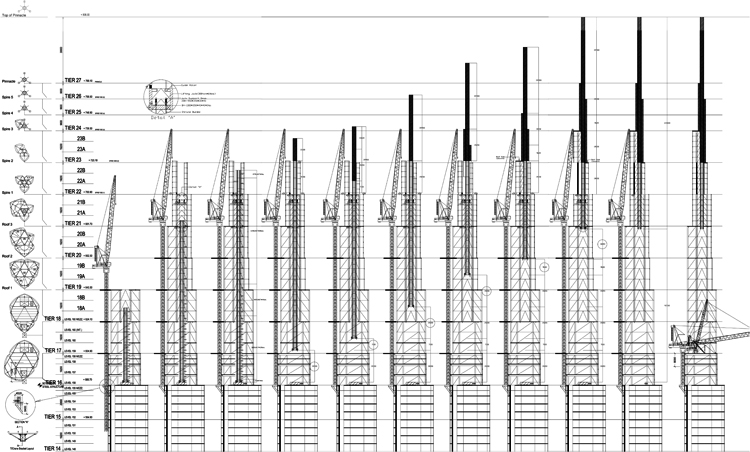

CONSTRUCTING THE BURJ SPIRE

Drawing showing the sequential construction of the Burj Khalifa spire. Courtesy of Samsung C & T.

It is one thing to draw a spire that reaches 828 meters into the air and to engineer the structure to support that height, but it is an added level of complication to figure out how it can be constructed.

Burj Khalifa is built of concrete with a jump-form system, up to level 156, where the tower is constructed of structural steel. As this drawing sequence from SOM illiterates, the steel was lifted and erected by a crane and derrick that was attached to the concrete core. The final 136 meters of the spire, a steel pipe weighing 350 tons, had to be assembled in sections within the tower, then jacked up into place. This method recalls the system used in the Chrysler Building in 1929, but at a much larger scale.

The following technical description of the erection of the spire prepared and executed by Samsung C & T, was provided by the construction project managers from Turner:

The spire at the Burj Khalifa is comprised of over twenty sections welded together to form a hollow steel structure over 110 meters long (inside the building and exposed). These steel sections were assembled within the main tower structure while it was being erected, and the completed spire pipe was then hydraulically jacked into final position over the course of eight separate lift cycles. The main construction sequence allowed for various tower structural members to be temporarily left out to accommodate the lifting equipment, which included three hydraulic strand jacks and a series of roller guides. The exposed portion of the spire’s exterior is equipped with stainless steel fins, which maintain the tower’s spiral geometry and optimize the wind flow across the structure.

Excerpts from a video of William F. Baker, Partner in Charge of Structural and Civil Engineering at Skidmore, Owings & Merrill LLP, 2007.

In the video above Baker describes the structural system of the Burj Khalifa.

View past exhibition: WORLD'S TALLEST BUILDING: BURJ DUBAI

View BURJ KHALIFA LECTURE SERIES including the full program with William F. Baker.